Tampa has a large number of logistics positions. There are many logistics jobs in Tampa. Some of them can be found in manufacturing, construction and healthcare. Others may work for wholesalers or consulting firms who help businesses streamline their supply chain.

A degree in Logistics can lead to a variety of career options. A degree in logistics can open up a number of career opportunities. Depending on what you want to do, and your goals, it may be best for you to choose a specialization in logistics.

BLS data predicts that careers in logistics will grow. Between 2018 and 2028, employment for these professionals is expected to increase by 5%. The projected job growth is even higher for professionals who specialize in business operations.

A four-year college or community college can offer a degree in logistics. These programs usually offer a wide range of logistics specializations. This allows you to develop more specialized skills, and make you more employable when you advance up the ladder.

As well as pursuing their bachelor's degrees, students are encouraged to take advantage of internships and networking events. These experiences give you valuable hands-on experience in the field, and they can help you find your first logistics job.

The logistics industry is a very diverse field, with good job prospects. You can find logistics jobs throughout the country, particularly in states that are large and growing, like California and Texas. You can also find careers in a number of specific sectors, such as aerospace and oil and gas.

Consider the size and capability of a company when selecting a logistics service. Ideally, you should select a 3PL that understands your business and can offer you a customized solution to meet your specific needs. It will help you reduce costs and improve efficiency.

Supply chain management is crucial to your business' success. To ensure that your product arrives at the correct time in perfect condition, you must have the appropriate people and tools. By selecting a third parties logistics provider with experience in your sector and who is able to deliver on time every time, you can increase the efficiency of your supply chains.

Sheer, a full-service 3PL based in Tampa, can increase the efficiency and speed of your supply chain as well as reduce your costs. We provide our customers with a range services including inventory management, transportation and shipping.

We offer a range of technology tools that will help you manage and track your supply chain. Our cloud-based system integrates with your existing ERP, allowing you to easily monitor and control your entire business.

Sheer can help you transform your supply chain into an asset by utilizing our multimodal freight network. You can also count on us to make sure that your products are delivered safely and on-time, every time.

FAQ

Is there anything we should know about Manufacturing Processes prior to learning about Logistics.

No. You don't have to know about manufacturing processes before learning about logistics. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

What does manufacturing mean?

Manufacturing Industries are those businesses that make products for sale. Consumers are the people who purchase these products. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They manufacture goods from raw materials using machines and other equipment. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

How can manufacturing prevent production bottlenecks?

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes planning for capacity requirements as well as quality control measures.

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma is a management method that helps to improve quality and reduce waste.

It seeks to eliminate variation and create consistency in your work.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

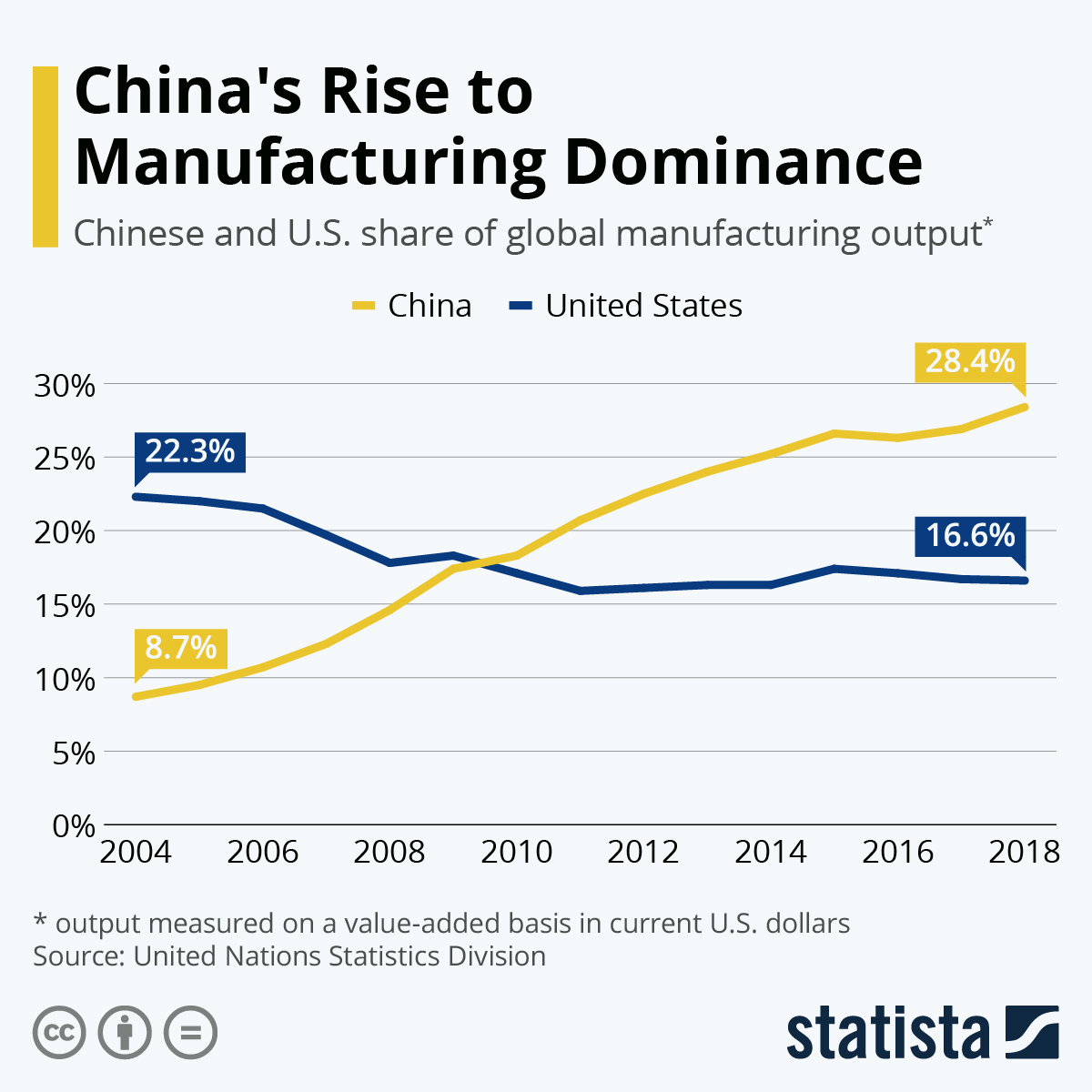

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the first book on lean manufacturing in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes the elimination of defects and waste throughout the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing practices are widespread in many industries. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Five fundamental principles underlie lean manufacturing.

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow - Make sure work runs smoothly without interruptions.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many businesses are now using lean manufacturing to improve their competitiveness. Some economists even believe that lean manufacturing can be a key factor in economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

The principles of lean manufacturing can be applied in almost any area of an organization. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three main types in lean manufacturing

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous improvement involves continuous improvement of processes and people as well as tools.