Manufacturing jobs come in many forms. These careers can range from assembly, fabrication, tool and die making, operations, quality control, and logistics. Advanced manufacturing is a great career choice. It offers more challenges, better pay and can lead to a rewarding life. In this article, you will learn about training pathways for these jobs. Here are some of these most common manufacturing jobs. Listed below are a few of these jobs.

Manufacturing jobs include production, manufacturing, logistics, management, assembly, fabrication, tool and die-making, operations, quality control and processing.

There are many kinds of manufacturing careers. There are many types of manufacturing jobs. As technology advances, so do the skills required to be proficient in digital technologies. These job descriptions require you to be organised, detail-oriented, and rational. While automation can't replace workers, it has improved the skills of workers. There is a high demand for manufacturing professionals, and the wages are often higher than for other occupations. Many manufacturing workers are offered retirement benefits and health insurance.

Other manufacturing jobs include designing, manufacturing, and modifying clothing, tools, or machines. A lot of jobs in this field require knowledge and understanding of physical quantities, such as stress, strains, vibration frequency, pressure, and so on. The machines and equipment that mechanical engineers use, as well as textile technicians and packaging technologists, require them to understand both the electrical and mechanical aspects of their work.

The responsibility of quality control is shared by all workers in a manufacturing company. Quality control workers, however, are responsible for monitoring production and ensuring that each part meets the company's requirements. They may provide feedback and oversight for quality control, as well as overseeing the production process. A manufacturing career in quality control could help you advance your career by gaining valuable experience and education.

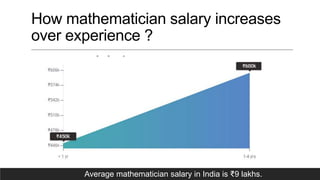

Advanced manufacturing jobs require more work, but better pay and a lot of success.

Advance manufacturing can offer more challenges, better pay and better career opportunities. This fast-growing industry relies on technology and innovation for its advancement and better products. For advanced manufacturing careers, you must be willing to work hard and sacrifice for higher wages. However, the rewards are well-worth the risks. These jobs are suited to the creative and innovative individual who enjoys doing challenging work. Manufacturing is a key industry for the future.

A college degree is typically required to hold a position in advanced manufacturing. A certificate from a post-secondary institution may be sufficient. Manufacturing-focused higher-ed programs introduce students to cutting-edge manufacturing technologies and methodologies. These programs might include supply chain logistics, green manufacturing, and others. Graduates of these programs will develop in-demand skills. High-skilled manufacturing jobs have many benefits. They offer a higher income, better benefits, and greater satisfaction.

The salary of an Advanced Manufacturing Engineer tends to be higher than that for a design engineer. This is because Advanced Manufacturing Engineers are typically more focused on design than on process capability. Although their skills may include solidworks and layout, Advanced Manufacturing Engineers make more money in Technology. They can enjoy life satisfaction through meeting challenging deadlines, and making a difference for others.

You can train to get a job as a manufacturing worker.

There are many options for training to help you get the education and training you need to be a successful manufacturing career. There are many career options in the manufacturing industry and high demand for skilled workers. Although manufacturing was once associated with unskilled workers and dark factories, modern manufacturing is an industry that has many exciting career opportunities. These careers are highly creative and lean.

A certificate in electrical engineering is necessary to be able to work as an assembler. You can also learn to be a welder or machinist, or a quality control specialist. The manufacturing industry needs many workers. You could even become a manager. As a way of increasing your earning potential, you can pursue a career in manufacturing.

As an entry-level employee in a factory, you can also learn how to work in manufacturing. Hudson Valley Community College has joined forces with several manufacturers to offer an Entry Level training program for those looking to enter the workforce. This project, partly funded by the Workforce Development Institute of New York, includes hands-on training and online classes. This program is ideal if you don't have time to complete a full certificate or degree program.

FAQ

Do we need to know about Manufacturing Processes before learning about Logistics?

No. You don't have to know about manufacturing processes before learning about logistics. Knowing about manufacturing processes will help you understand how logistics works.

What does it mean to be a manufacturer?

Manufacturing Industries are companies that manufacture products. Consumers are people who purchase these goods. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They create goods from raw materials, using machines and various other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

Is it possible to automate certain parts of manufacturing

Yes! Automation has been around since ancient times. The wheel was invented by the Egyptians thousands of years ago. To help us build assembly lines, we now have robots.

Actually, robotics can be used in manufacturing for many purposes. They include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Manufacturing can also be automated in many other ways. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

What is the responsibility of a logistics manager?

Logistics managers ensure that goods arrive on time and are unharmed. This is done by using his/her experience and knowledge of the company's products. He/she should ensure that sufficient stock is available in order to meet customer demand.

How can I learn about manufacturing?

You can learn the most about manufacturing by getting involved in it. However, if that's not possible, you can always read books or watch educational videos.

What are the 4 types of manufacturing?

Manufacturing is the process that transforms raw materials into useful products. It can involve many activities like designing, manufacturing, testing packaging, shipping, selling and servicing.

What does warehouse mean?

Warehouses and storage facilities are where goods are kept before being sold. You can have it indoors or outdoors. Sometimes, it can be both an indoor and outdoor space.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

Six Sigma in Manufacturing:

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma seeks to reduce variation between the mean production value. If you take a sample and compare it with the average, you will be able to determine how much of the production process is different from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding how variability works in your company is the first step to Six Sigma. Once you have this understanding, you will need to identify sources and causes of variation. This will allow you to decide if these variations are random and systematic. Random variations happen when people make errors; systematic variations are caused externally. If you make widgets and some of them end up on the assembly line, then those are considered random variations. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

After identifying the problem areas, you will need to devise solutions. That solution might involve changing the way you do things or redesigning the process altogether. After implementing the new changes, you should test them again to see if they worked. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.