Before you start looking for a job, think about how much you can make. This article will tell you the average salary, what kind of work environment is available, and how much you can expect to grow your job. You can also find out what training programs are offered. Additionally, you will learn what skills are required to succeed within this field. Learn how to land the next great sales position. And don't forget to check out our related articles below!

Average annual salary

According to U.S. Bureau of Labor Statistics sales representatives working in the wholesale and industrial manufacturing industry earn an average salary of $61,600 annually. Salary statistics were calculated from a nationwide survey that was completed in 2021. The results were released in April 2022. This article will talk about average salaries of these representatives. By selecting your location, you can view the average salary ranges for your state. This job is available in many locations, with a slightly higher average salary than the national average.

Sales for wholesale and manufacturing jobs combine a love of selling goods and marketing. You will work as a wholesale sales representative and sell products from wholesalers to businesses. Sales representatives deal with customer inquiries, negotiate prices, and explain the features of products to customers. They can also manage sales or marketing campaigns. They may also manage administrative duties such as travel arrangements or expense accounts filing. Listed below are the salary ranges for sales representatives in wholesale and manufacturing.

Work environment

According to the U.S. Bureau of Labor Statistics (USBoLS), sales representatives in manufacturing and wholesale industries are expected to see a seven percent increase in employment from 2008 to 2022. This rate is faster than the average for all occupations. This will be due to the expansion of goods in the economy. The key role of sales representatives is to transfer those goods. They are required to attend sales meetings and conventions as well as attend college and study trade literature.

Sales representatives from the wholesale and manufacturing industry provide support for clients after they have been hired. They help their clients with merchandising and advertising, as well as preparing bids and estimates for customers. They are responsible for managing customer accounts and handling other administrative tasks, including scheduling appointments, filing expense bills, and making travel arrangements. Although the work environment for sales representatives in wholesale and manufacturing industries varies, there is a wide range of job opportunities available for those with the right skills.

Training programs

Training new salespeople should include the application of skills in real-world situations, such as using products. Experienced salespeople can demonstrate product features, and product engineers can teach trainees about its technology. To connect potential customers with the resources they need, new representatives should be familiarized with the marketing content library. A sales demonstration by an experienced salesperson should be shown to them and they should practice a mock pitch. You should also train in product knowledge.

Some companies offer formal training programs to begin sales representatives. These programs may last for up to a year, and trainees rotate between job functions in factories and offices. On-the-job training may be provided, as well as seminars on various sales techniques. Promotion usually comes in the form of more territory and higher commissions. If trainees have good sales records, they may move up to higher responsibilities. A sales manager or department should be consulted if the sales representative has not had any training in this field.

Job growth

Sales representatives in wholesale or manufacturing industries will grow at approximately the same rate that the overall labor force. This occupation will see less job growth than other occupations. The average American currently works until his or her 60s. This job offers low stress, a good work-life mix, solid prospects of advancement, and a high potential for pay increases. You may need to travel for this job, but it's rewarding and has high potential for growth.

There are many factors which determine the growth prospects for sales representatives in wholesale or manufacturing. The job requires substantial knowledge of the products that are sold. While most wholesale and manufacturing sales representatives work for one company while others represent several companies, many of them are also employed by multiple companies. These sales representatives are also responsible for negotiating with retail merchants to increase the product's exposure. Sales representatives can also be reached out to customers on a regular basis, set up appointments, and manage administrative tasks like expense accounts.

FAQ

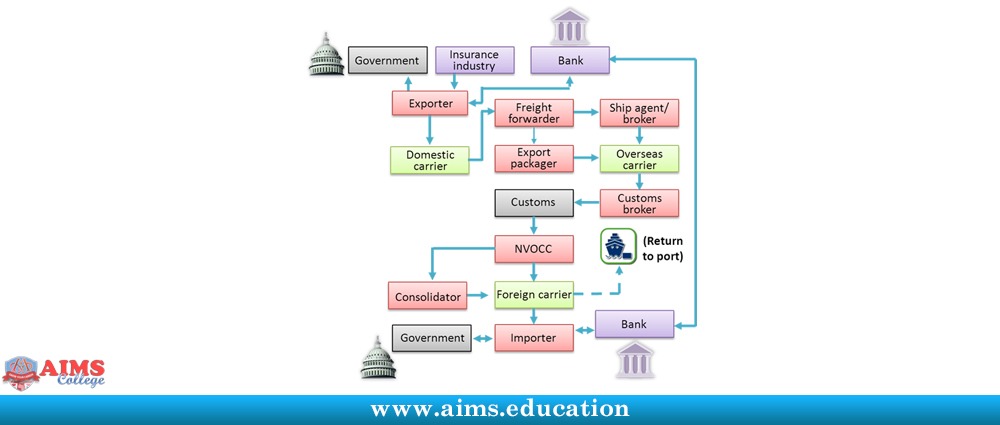

What are the goods of logistics?

Logistics refers to the movement of goods from one place to another.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure the product reaches its destination in the most efficient manner. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

What is the job of a logistics manger?

A logistics manager ensures that all goods are delivered on time and without damage. This is done by using his/her experience and knowledge of the company's products. He/she should ensure that sufficient stock is available in order to meet customer demand.

What is the role of a manager in manufacturing?

A manufacturing manager has to ensure that all manufacturing processes work efficiently and effectively. They should also be aware of any problems within the company and act accordingly.

They should also know how to communicate with other departments such as sales and marketing.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

How can manufacturing avoid production bottlenecks

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes planning to meet capacity requirements and quality control.

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It emphasizes consistency and eliminating variance in your work.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use 5S to increase Productivity in Manufacturing

5S stands as "Sort", Set In Order", Standardize", Separate" and "Store". Toyota Motor Corporation created the 5S methodology in 1954. This methodology helps companies improve their work environment to increase efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. Cleaning, sorting and packing are all done daily. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step has a different action and leads to higher efficiency. For example, when you sort things, you make them easy to find later. You arrange items by placing them in an order. Then, after you separate your inventory into groups, you store those groups in containers that are easy to access. Finally, label all containers correctly.

Employees will need to be more critical about their work. Employees must understand why they do certain tasks and decide if there's another way to accomplish them without relying on the old ways of doing things. In order to use the 5S system effectively, they must be able to learn new skills.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. They are more motivated to achieve higher efficiency levels as they start to see improvement.