The right qualifications are essential if you want to work as a maintenance engineer. These certifications are required and what you can expect to earn. If you have an eye for detail, the job of maintenance engineer is for you. Maintenance engineers are responsible to maintain a building's infrastructure, and make sure it is operating at peak performance.

Qualifications for a career in maintenance engineering

You should consider these key points if you're looking for a job as a maintenance engineer. While a highschool diploma will provide you with the foundational skills needed, you might also be interested in taking an engineering course at college. It will be beneficial to take courses in chemistry and math. You can also gain work experience. A technical school may be an option depending on the needs and interests of your company.

Maintenance engineers are responsible both for the maintenance and repair of machinery and equipment. They are responsible for maintaining industrial machinery as efficient as possible. They also supervise the supply of spare parts. Some jobs, especially those in manufacturing, require shift work. Depending on the type of work, maintenance engineers can advance to management positions or even pursue other areas of employment in related industries. They can also start their own businesses once they have gained enough experience.

Maintenance engineers make between PS20,000 to PS25,000 an average. But salaries can vary depending on where you work, how big the company is, and what industry you are in. You can also become a maintenance engineer and move up to management roles, which require leadership skills. Chartered status may also help with career progression.

Certifications are required

As a maintenance engineer, you may be required to hold several certifications. These certifications can be specific or general in nature. They may also cover hazardous materials handling. The International Maintenance Institute offers professional certification at several levels. These include certified maintenance technicians at lower levels, and maintenance managers at higher levels.

Consider your educational background before you consider becoming a maintenance technician. While most certification providers don't require specific educational qualifications, some recommend a high school diploma or GED. This is the minimum requirement for most employers and recruiters. However, you can also obtain a certification without a degree if you've had previous work experience in a similar industry.

Although a bachelor's in engineering is not required for maintenance engineers, a degree from an appropriate field can help you stand out. A degree in electrical engineering, mechanical engineering, or facilities management may be useful. Even if a degree in engineering is not necessary, you could find work as either a maintenance technician or working your way up to maintenance engineer with experience and training.

Salary

Although the Bureau of Labor Statistics doesn't monitor the salaries of maintenance engineers, it projects job growth in related areas. For example, general maintenance workers and mechanical engineers are expected to grow by eight percent, and construction management managers may see an 11 percent increase in employment. Consider a career for maintenance engineers if you're interested in this job. You can either look for entry-level or high-growth jobs in these industries.

Maintenance engineer salaries: The median 2008 salary for maintenance engineers stood at $88,570. The lowest 25 per cent earned $48,270 and the highest ten percent earned over $110,310.

FAQ

What is production management?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. This document is designed to make sure everything is ready for when you're ready to shoot. You should also have information to ensure the best possible results on set. This information includes locations, crew details and equipment requirements.

The first step is to outline what you want to film. You may have decided where to shoot or even specific locations you want to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. One example is if you are unsure of the exact model you want but decide that you require a car. If this is the case, you might start searching online for car models and then narrow your options by selecting from different makes.

After you have selected the car you want, you can begin to think about additional features. Do you have people who need to be seated in the front seat? Or maybe you just need someone to push the car around. Maybe you'd like to change the interior from black to a white color. These questions will help you determine the exact look and feel of your car. You can also think about the type of shots you want to get. Are you going to be shooting close-ups? Or wide angles? Perhaps you want to show the engine or the steering wheel? This will allow you to determine the type of car you want.

Once you've determined the above, it is time to start creating a calendar. You can use a schedule to determine when and where you need it to be shot. A schedule for each day will detail when you should arrive at the location and when you need leave. Everyone will know what they need and when. It is possible to make arrangements in advance for additional staff if you are looking to hire. It is not worth hiring someone who won’t show up because you didn’t tell him.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects can be completed in a matter of days or weeks. Others may take several days. When creating your schedule, be aware of whether you need more shots per day. Multiple shots at the same location can increase costs and make it more difficult to complete. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Another important aspect of production planning is setting budgets. You will be able to manage your resources if you have a realistic budget. You can always lower the budget if you encounter unexpected problems. But, don't underestimate how much money you'll spend. You will end up spending less money if you underestimate the cost of something.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

What are my options for learning more about manufacturing

Hands-on experience is the best way to learn more about manufacturing. You can also read educational videos or take classes if this isn't possible.

What is the importance of automation in manufacturing?

Automation is essential for both manufacturers and service providers. It allows them provide faster and more efficient services. It reduces human errors and improves productivity, which in turn helps them lower their costs.

What are the products of logistics?

Logistics refers to the movement of goods from one place to another.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians ensure the product reaches its destination in the most efficient manner. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

What are the four types in manufacturing?

Manufacturing refers to the transformation of raw materials into useful products by using machines and processes. Manufacturing involves many activities, including designing, building, testing and packaging, shipping, selling, service, and so on.

How can manufacturing reduce production bottlenecks?

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes planning for both capacity requirements and quality control measures.

The best way to do this is to use continuous improvement techniques such as Six Sigma.

Six Sigma management is a system that improves quality and reduces waste within your organization.

It's all about eliminating variation and creating consistency in work.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

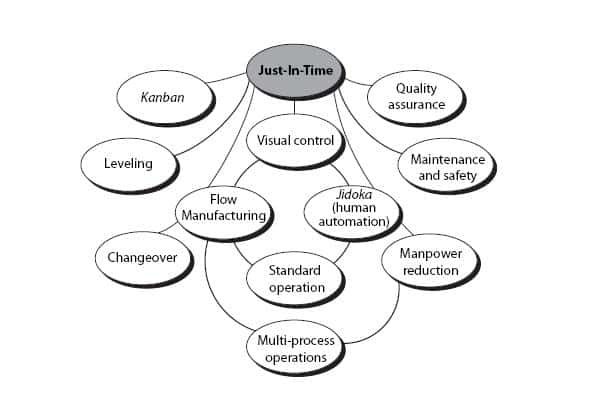

How to Use the Just In Time Method in Production

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. It allows you to get the right amount resources at the right time. This means you only pay what you use. Frederick Taylor, a 1900s foreman, first coined the term. He noticed that workers were often paid overtime when they had to work late. He concluded that if workers were given enough time before they start work, productivity would increase.

JIT is a way to plan ahead and make sure you don't waste any money. Also, you should look at the whole project from start-to-finish and make sure you have the resources necessary to address any issues. You can anticipate problems and have enough equipment and people available to fix them. This will ensure that you don't spend more money on things that aren't necessary.

There are many JIT methods.

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will enable you to keep track of how much material is left after you use it. This will allow to you estimate the time it will take for more to be produced.

-

Inventory-based : You can stock the materials you need in advance. This allows one to predict how much they will sell.

-

Project-driven: This is an approach where you set aside enough funds to cover the cost of your project. When you know how much you need, you'll purchase the appropriate amount of materials.

-

Resource-based JIT : This is probably the most popular type of JIT. Here, you allocate certain resources based on demand. If you have many orders, you will assign more people to manage them. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This is very similar to cost-based, except that instead of looking at how much each individual worker costs, you look at the overall price of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based JIT: A variation on resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of focusing on the cost of each worker or how long it takes, think about how high quality your product is.

-

Value-based: This is one of the newest forms of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based. This method is inventory-based and focuses only on the actual production at any given point. This method is useful when you want to increase production while decreasing inventory.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It is essential because it reduces lead-times and increases throughput.