Before you start your search for a job, consider how much you can earn. You'll find the average annual salary, job growth, and the type of work environment in this article. Also, you can find out which training programs exist. This will allow you to learn about the necessary skills to succeed in this area. Find out how you can land your next major sales position. You can also check out the related articles below.

Average annual salary

According to the U.S. Bureau of Labor Statistics the average annual income for sales reps in the wholesale and manufacturing industries is $61,600. The salary statistics are based upon a national survey that was done in 2021. The results were published on April 20, 2022. This article will provide information on average salaries for these individuals. By selecting your location, you can view the average salary ranges for your state. You will find many job opportunities in this field, and the average salary may be a bit higher than the national one.

You can combine your love for marketing and selling products to make a career in wholesale or manufacturing sales. As a wholesale sales representative, you will sell goods from manufacturers and wholesalers to businesses. Sales representatives assist customers with their inquiries and negotiations. They also explain the product features and negotiate pricing. They can also manage advertising and sales campaigns. They may also handle administrative duties, such as filing expense accounts and making travel arrangements. Below are the salaries for wholesale and manufacturing sales representatives.

Work environment

According to the U.S. Bureau of Labor Statistics (USBoLS), sales representatives in manufacturing and wholesale industries are expected to see a seven percent increase in employment from 2008 to 2022. This rate is faster than the average for all occupations. This will be due to the expansion of goods in the economy. It is the sales reps who play a crucial role in transferring these goods. Sales representatives must attend trade shows and conventions, as well as read trade literature.

Once hired, sales representatives in wholesale and manufacturing industries provide on-going support to clients. Their clients are assisted with advertising and merchandising, and they prepare bids and estimates. They handle customer accounts as well as other administrative tasks like scheduling appointments, filing expense reports, and making travel arrangements. Although the work environment for sales representatives in wholesale and manufacturing industries varies, there is a wide range of job opportunities available for those with the right skills.

Training programs

Sales representatives must be able to apply their skills and use products when training them. Product engineers and experienced salespeople can help new trainees to learn about its technology. To connect potential customers with the resources they need, new representatives should be familiarized with the marketing content library. They should also observe a sales demo by an experienced salesperson, and perform a mock sales pitch. Product knowledge should be emphasized, including its creation as well as its usage.

Many companies offer training programs to help salespeople get started. These programs may last for up to a year, and trainees rotate between job functions in factories and offices. On-the-job training may be provided, as well as seminars on various sales techniques. Promotion is usually in the form a bigger territory with higher commissions. With good sales records, trainees may progress to higher levels of responsibility. Sales reps who have not received any sales training should consult their sales manager for assistance.

Employment growth

Sales reps in manufacturing and wholesale industries will see their earnings grow at the same pace as the rest of the labor market. This occupation will see less job growth than other occupations. The average American currently works until his or her 60s. This job offers low stress, a good work-life mix, solid prospects of advancement, and a high potential for pay increases. This job requires some traveling but is very rewarding with high career potential.

There are many factors that impact the growth of jobs for wholesale and manufacturing sales representatives. The job requires substantial knowledge of the products that are sold. While most wholesale and manufacturing sales representatives work for one company while others represent several companies, many of them are also employed by multiple companies. They also negotiate with retailers to increase product exposure. Sales representatives contact customers to schedule appointments and take care of administrative tasks, such as filing expense reports.

FAQ

How can we increase manufacturing efficiency?

First, determine which factors have the greatest impact on production time. We then need to figure out how to improve these variables. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you identify them, look for solutions.

What is the responsibility of a production planner?

Production planners ensure all aspects of the project are delivered within time and budget. They also ensure the quality of the product and service meets the client's requirements.

Can we automate some parts of manufacturing?

Yes! Yes. Automation has been around since ancient time. The Egyptians discovered the wheel thousands and years ago. Robots are now used to assist us in assembly lines.

There are many applications for robotics in manufacturing today. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation could also be used to improve manufacturing. For instance, 3D printing allows us make custom products and not have to wait for months or even weeks to get them made.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. No. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

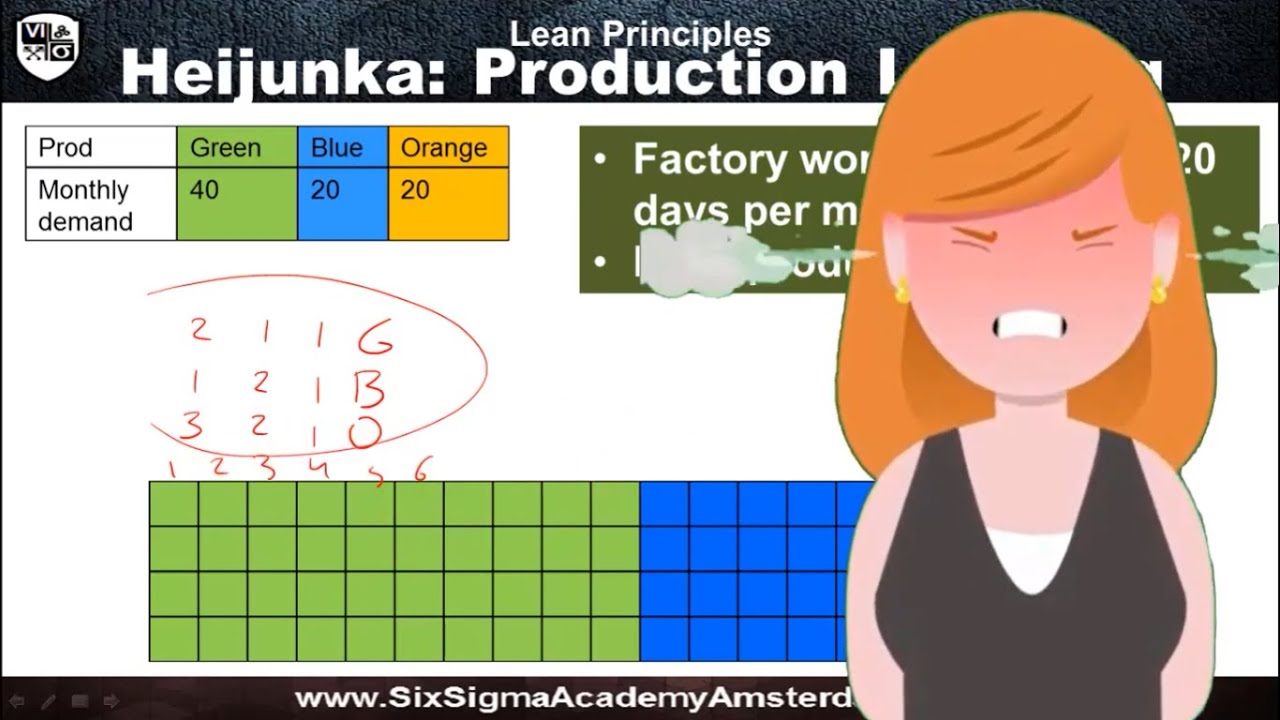

How to use Lean Manufacturing in the production of goods

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the "The Machine That Changed the World", the first book about lean manufacturing. It was published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination and minimization of waste in the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing can be found in many industries. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Lean manufacturing includes five basic principles:

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Although lean manufacturing isn't a new concept in business, it has gained popularity due to renewed interest in the economy after the 2008 global financial crisis. Many businesses have adopted lean production techniques to make them more competitive. Economists think that lean manufacturing is a crucial factor in economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

You can apply Lean Manufacturing to virtually any aspect of your organization. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types in lean manufacturing

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT means that components are assembled at the time of use and not manufactured in advance. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

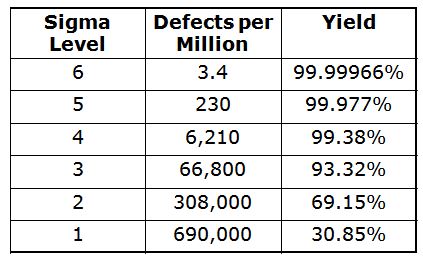

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. If a part is required to be repaired on the assembly line, it should not be scrapped. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous Improvement involves continuous improvement of processes.